- Home

- /

- Computerised Maintenance Management Systems...

CMMS+EAM 4FACTORY

Comprehensive maintenance and asset management solution for manufacturing

Have you wondered which solution would be better for your production plant? CMMS or EAM system?

We have a ready solution for you!

A system that meets the requirements of both solutions.

CMMS+EAM 4FACTORY

What can our CMMS+EAM 4FACTORY solution do?

Manage all your company’s fixed assets with one complete application:

CMMS – everything directly related to the production process and, thanks to the EAM – functionality, the company’s other fixed assets.

Manage all your company’s assets with one complete application

EAM – other fixed assets of the company

3 working environments

APPLICATION - TERMINAL - PORTAL

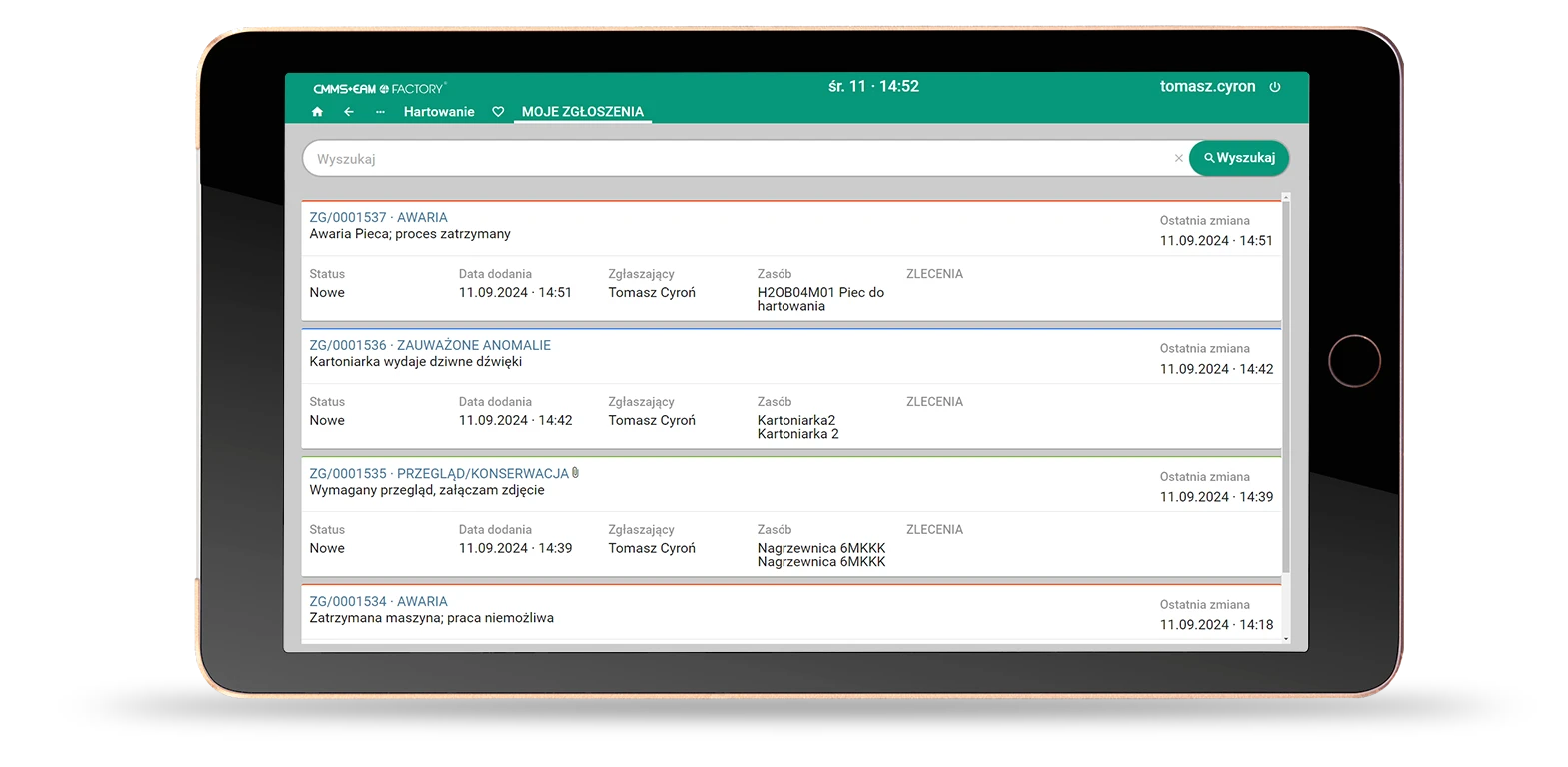

MOBILE APPLICATION

receive push notifications, incidents registration

TERMINAL

fast login for direct operation by any employee, publishing and viewing of instructional videos, possibility of installation in so-called kiosks, publishing and reading written instructions

OPERATIONAL AND ADMINISTRATIVE PORTAL

complete intuitive system configuration

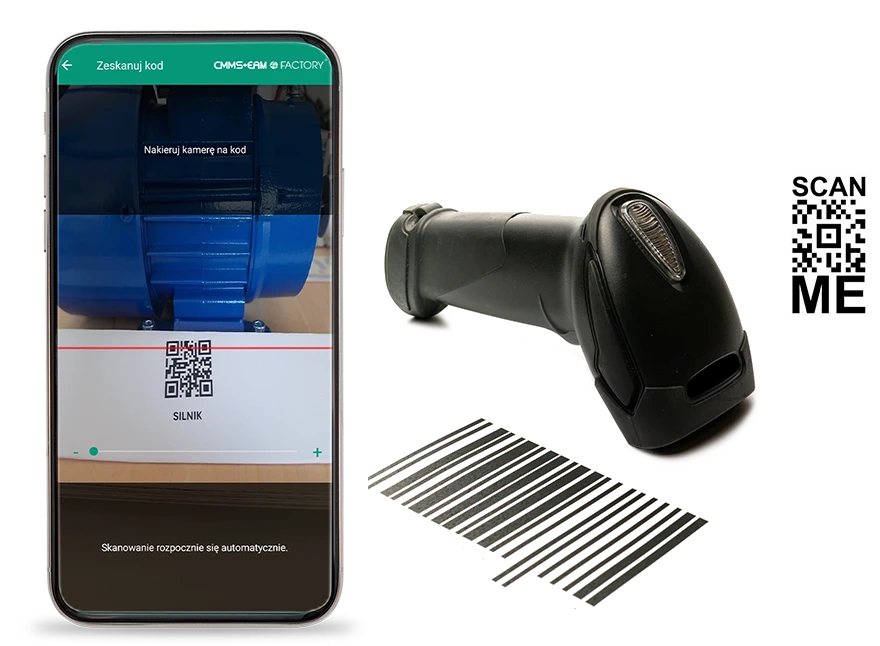

Barcode and QR code support with both smartphone/tablet and handheld scanners

Mobile application supports barcodes and QR codes

Tag resources and parts with barcodes or QR codes – save time when creating requests and retrieving parts from stock

For the Notification module:

intuitive request creation

For the Orders module:

quick identification of orders

For the Parts module:

quick identification of parts in the system

Adding photos/pictures

For the Orders module:

to make it easier to indicate the exact location of a breakdown/machine part.

In production, when time is of the essence, there is not always time to give a detailed description. A picture can be worth a thousand words.

For the Resources module:

ability to upload thumbnails to help identify resources.

For the Outline module:

add attachments: document the steps of the review to make your work easier in the future. A dry description is not always intuitive to read. The image completes the message.

Easy export of data in XLSX format

Full cost control

CMMS+EAM 4FACTORY solution is ready to be implemented with other production support systems

Try CMMS+EAM 4FACTORY free version

Fill in the form with your details and once submitted you will be given access to a free trial of the programme.

Comprehensive maintenance and asset management solution for manufacturing

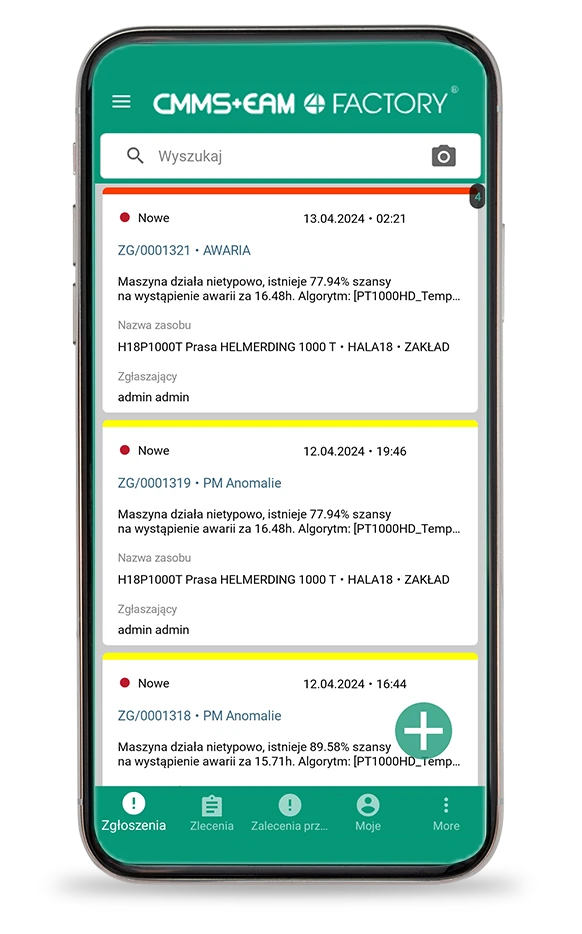

CMMS+EAM 4FACTORY Mobile App

- Easy to use

- Available in Google Play Store and AppStore

- Push Notifications

- Quickly create notifications using barcodes and QR codes

- Manual resource search

- Manage requests

- Time control

CMMS+EAM 4FACTORY Terminal

- Unlimited number of reporting users

- Possibility to install kiosks on the shop floor

- Possibility to display dashboards

- The terminal is clear and easy to read and can be installed on the shop floor on any device with access to a web browser

- Ability to report incidents

- Ability to perform inspections, read instructions and view multimedia materials

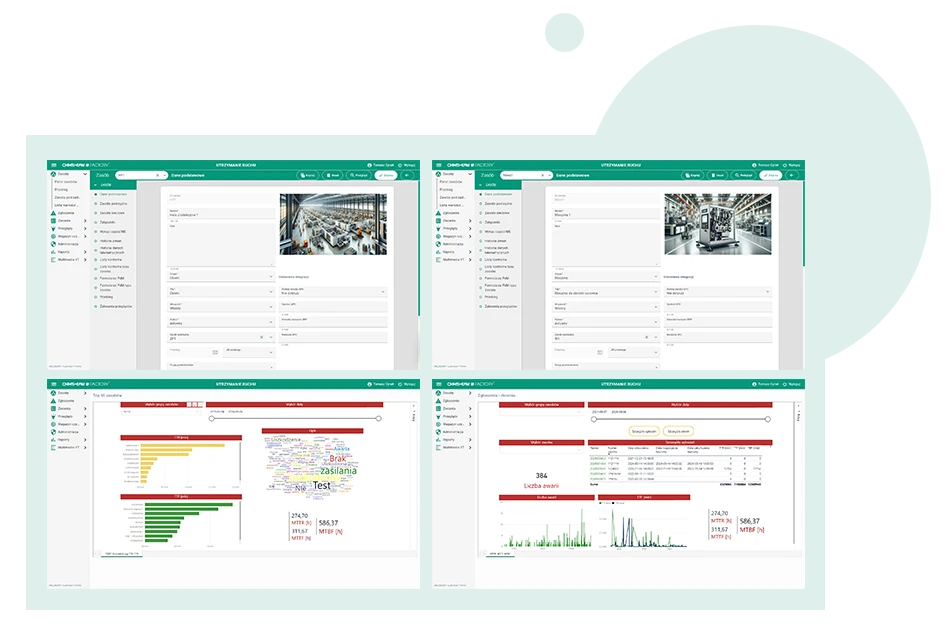

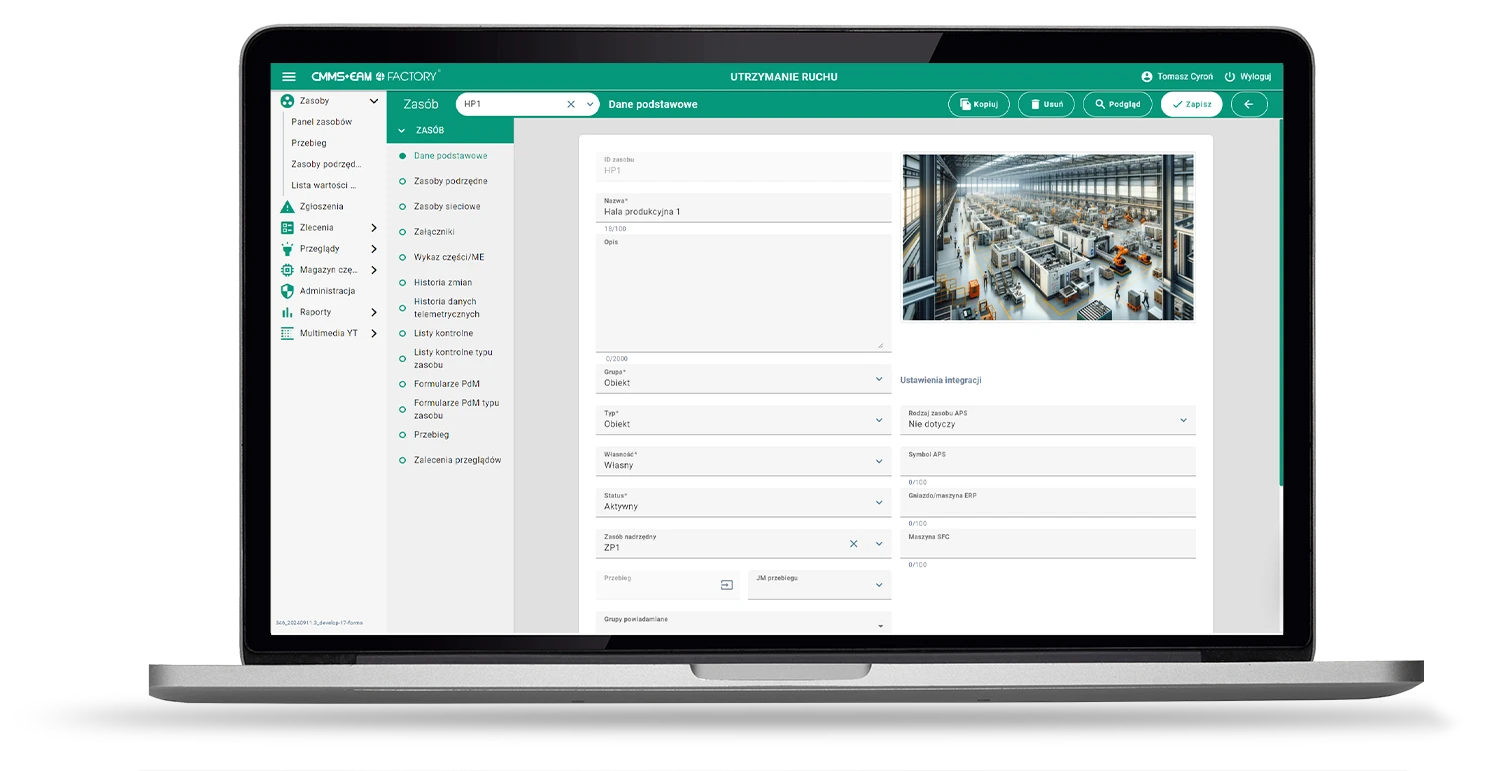

CMMS+EAM 4FACTORY Portal

- Intuitive navigation panel for easy system management

- Choice / order / width of columns depends on user

- Fully configurable by user or by DSR specialists

Among others, our solutions are used by

Allows you to know the real cost of breakdowns and preventive work. Allows the analysis of the real cost of repairs, maintenance and activities of the Maintenance Department (MD) related to the elimination of breakdowns. The issue of parts and consumables, as well as the recording of MDs working time, is carried out on orders directly linked to resources (machines, equipment, production lines and other fixed assets).

Organises the list of fixed assets held, including the register of machinery and equipment and other assets, with additional technical attributes describing each asset. Allows the addition of attachments in the form of Technical Documentation (TD), photographs, purchase invoices and other necessary documents. This facilitates the sharing of technical documentation in electronic form with all employees.

Improves ergonomics for Maintenance Department and production by enabling mobile applications and terminal versions.

Shortens the time it takes to report an incident to the engineering department. Production interruption data is generated in real time, and the system also notifies relevant users of recorded incidents via mobile devices.

It automatically creates a maintenance plan in the form of maintenance recommendations generated (also automatically) in CMMS+EAM 4FACTORY according to a fixed maintenance schedule.

It supports the full path for ordering and inventory management of spare parts and consumables.

Enables the reduction of breakdowns through the efficient management of predictive, preventive and emergency events using AI (Artificial Intelligence) and ML (Machine Learning) based on AI 4FACTORY tools.

It enables optimal maintenance forecasting, problem identification before failure and performance optimisation, thanks to the integration of IOT 4FACTORY and AI 4FACTORY tools based on artificial intelligence for real-time machine monitoring.

The CMMS+EAM 4FACTORY system easily adapts to the changing needs of the company and integrates with other systems in the company, such as the ERP or MES system.